3 Elements for a Successful Lift Plan

A lift plan is essential to ensuring the safety and success of a complex lift. Taking the time to plan and organise your lift will keep site personnel, the load, and the crane safe, while ensuring Premier gets the job done within schedule and on budget. So what is the key to creating a successful lift plan?

It’s important to note that every lift is different, and lift plans are created based on the variables of the specific environment, payload, crane type and conditions. The following information is recommended as a basic guide to a successful lift plan.

Why is a lift plan important?

If you are requiring a crane to conduct a complex lift, then the team at Premier will need to create a lift plan with you. Not only are lift plans essential for assuring the safety of the crane, personnel, and the site, but it also helps to streamline the process and ensure costs do not exceed budgets. A lift plan is a highly useful document which will outline the type and size of crane, rigging equipment as well as the right personnel team for the lift.

What should a lift plan include?

Every successful lift plan should have risk assessments, method statements (how the lift will be executed), technical information (such as crane set up) and any other relevant documentation and information including schedules, maps, condition reports, drawings and photographs.

It should also include everyone involved in the lifting operation and their specific responsibilities and roles. The risk assessment should identify all hazards and how they will be negated or minimised.

A successful lift plan will have all the necessary documentation, but still be clear and concise.

How Premier creates a lift plan

There is a range of different approaches Premier takes when creating your lift plan. With our extensive in-house planning and programming team of engineers, we have helped thousands of clients on construction, infrastructure and other projects successfully create their lift plans. We recommend considering the following three different elements in order to create your lift plan.

Load

What we are lifting will determine how we lift it, so the load is an essential element to consider when planning your lift. The first step is to analyse the load weight, dimensions, lifting points, and centre of gravity. These factors will determine how we design the rigging arrangements including the chain slings, shackles, synthetic slings or spreader bars, and will need to be detailed in your lift plan with relevant drawings and documentation. It’s wise to have as much detail about the load Premier intended to lift in your plan as possible since it will inform every other aspect of your lift operation.

The Site

Where we are performing the lift is the next crucial factor we need to consider when creating a lift plan. Reviewing the site should begin with the cranes access area, any restrictions, or local council regulations that must be adhered too. Premier will likely ask the following questions. How is the load getting transported onsite? Where can the crane and personnel access the site? Where will be the crane set up area?

Your access points will help inform us and confirm the suitable setup locations. When reviewing the setup locations look for any overhead obstructions, the condition of the ground bearring, and take note of any potential hazards to then plan accordingly for. It’s also important to note if there are any areas that the crane cannot pass over during the lift.

The lift destination can sometimes be forgotten as people concentrate on the crane setup when planning their lift operations. How will we remove the load from the rigging equipment? Are there any obstacles, hazards or access restrictions?

The Crane

The combination of the above two factors will then help Premier determine the crane required for the job. By this stage, we should have a thorough understanding of the load and site conditions, which will help us choose the right crane size that has the necessary capabilities to do the job. It’s essential that our crane crew check that the crane and all rigging equipment has been inspected, and is in condition and ready to use before the lift goes ahead.

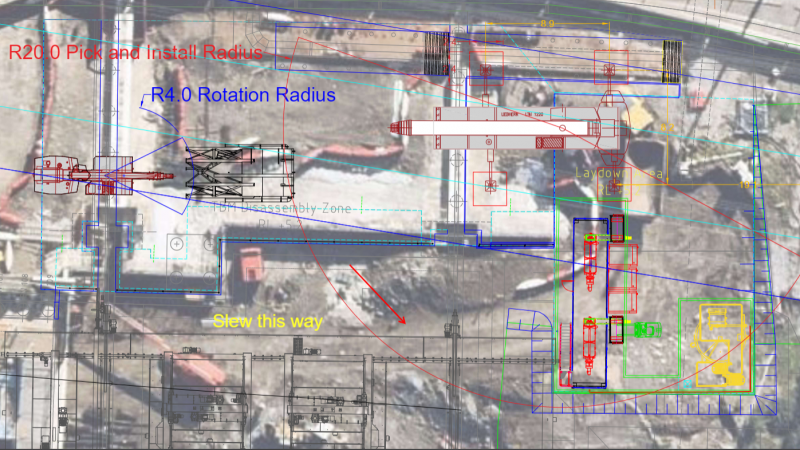

Premier’s planning team will decide upon the crane configuration, outline the execution parameters and organise the lifting crew. The diagrams of our crane may include more than just where the crane will be located, we can also add information about slew direction and restrictions, as well as any site boundaries as required.

While wind speed varies on the lift height, it needs to be accounted for within our lift plan. Premier’s crane will have a recommended wind speed window to operate within and wind limits for specific boom configurations. These limits can not be ignored as they may result in our crane overturning or damaging the load.

Recommended software

We recommend using the following software programs when creating your lift plan.

CAD Software is ideal for drawing the dimensions of your crane and load. It provides a site view of how the crane will sit onsite, how it looks when performing the lift, and how far the crane will reach to pick and install the load. It also provides a side elevation view that also shows how the rigging equipment is used.

Liccon Work Planner is used for planning the specifics of your lift. It shows the operator the ground pressure, hoist height, and radius parameters. It’s also used on the computer on the crane itself.

We use a Bluebeam PDF Editor to put together our lift plans and ensure they are a cohesive and attractive document that is ready to present.

Need help collating information for a lift plan?

If you’re new to planning lifts or are creating one for a particularly heavy or complicated lift, you can ask Premier ‘the experts’ for help. With more than twelve years of experience, we can assist you in creating a tailored plan specific to your lifting requirements. Get in touch with us today to discuss your lifting operations.