Project Summary

Client: CPBJH Joint Venture Tunnels

Location: 111 Whitehall Street, Yarraville (West Gate Tunnel, North Portal)

Crane: Liebherr LTM1250-5.1

Project Overview

PROJECT OVERVIEW: Premier was contracted by CPBJH to install three precast abutments to form the new tunnel driveway at the north portal of the WGTP tunnel zone. With existing structures in place and works continuing onsite, precision planning & execution was crucial to ensure successful results for our client.

CHALLENGE: With the gantry walkway beam already in place, Premiers team was facing tight head room challenges, as the height to do the lifts was only 14.7 meters.

Additionally, there was limited space for the crane tail swing, and set up area, which was also on a slope. For the safety of the operator, riggers and other workers onsite, getting the crane set up level was crucial to ensure maximum stability and lifting capacity.

Due to space constraints and only a single lane access road available, there was no room for the trucks to bring the counterweight and abutments near Premier’s 250t crane.

Moreover, as the lifts and installations were taking place in front of TBM holes 1 & 2, Premier’s crews had to deliver the required results within a strict time frame to avoid delaying other contractors onsite.

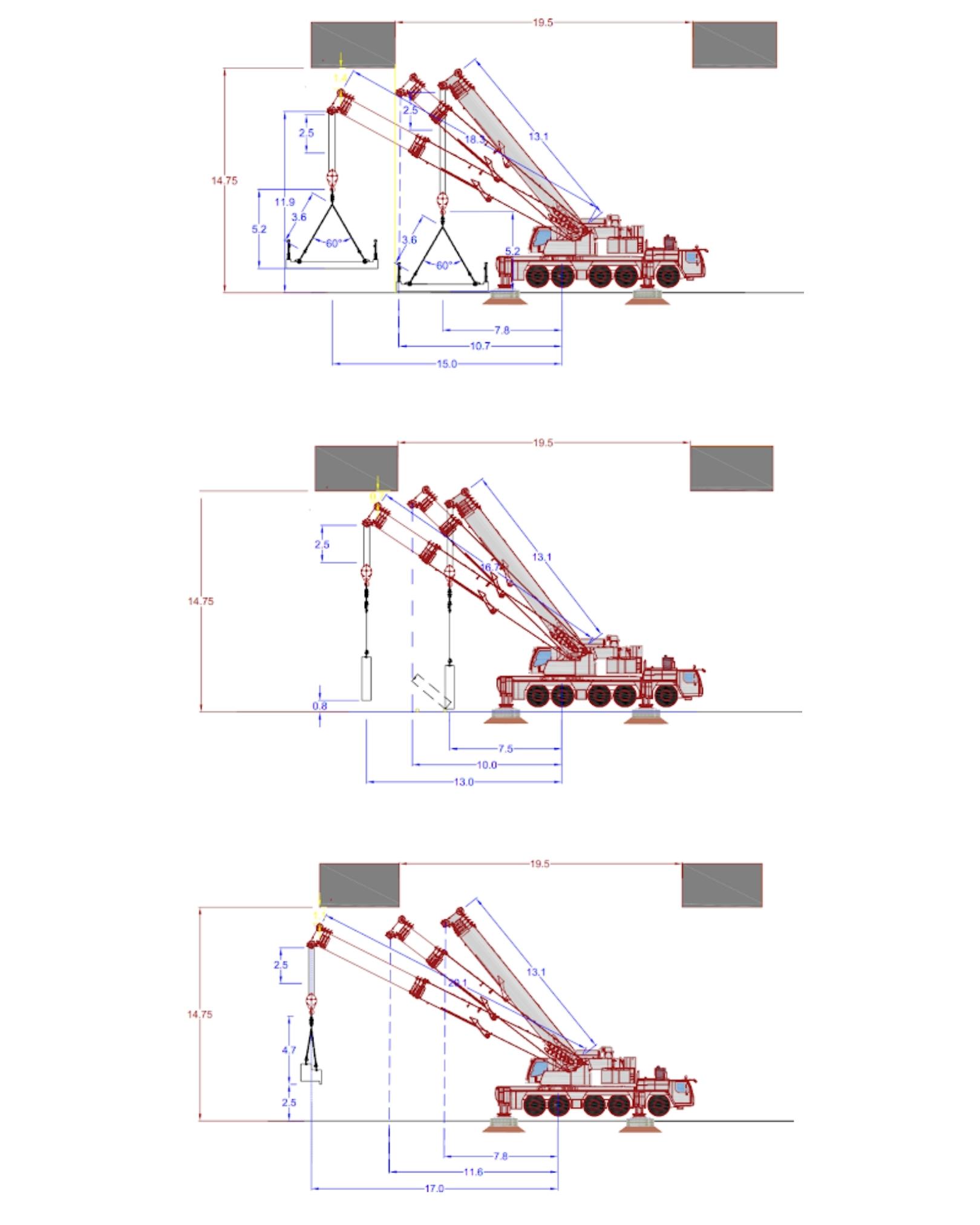

SOLUTION: As a result of the limited head space, Premier’s Engineering Team developed a telescoping elevation lift plan to tele-out the boom while holding the load. Following careful assessment it was agreed that this was the best solution taking all factors into consideration.

Since the specifications of each precast item were different, a unique lift plan for each item was developed including custom rigging configurations. Taking into account the limited head height, the team utilised specialised rigging gear to shorten the rigging height and hence allow more room for boom movements.

In terms of setting up on a slope, our crews used extra polys and bogmats to ensure the crane was completely level and safely set up for the lift execution.

With the option of driving trucks down the tunnel to bring the crane counterweight and abutments out of the picture due to limited space, we looked for alternative ways to access desired pick up locations. This led to using another 400t crawler crane (CPB400T), which lifted the counterweight and precasts from above the tunnel and positioned them in the lower ground level within radius for Premier’s 250t all-terrain crane. As part of the tight set up area challenges, on the TBM1 inbound portal, we short blocked the outriggers to 7.2m instead of full extension at 8.3m on our LTM1250.

Premier’s field crews worked around the clock doing consecutive day and night shifts to ensure the clients objectives were progressively met. The key to conducting efficient onsite operations was clearly defining the responsibilities of each field crew member onsite and maintaining clear communication throughout.

Involving Premier in the pre-planning process can help you avoid wasted resources. How?

When our client CPBJH Joint Venture Tunnels involved Premier in the early planning stages for these works, we were able to provide guidance on the required site conditions before the project commenced. Therefore only 3 columns were built prior to the lift, allowing just enough space for our crane to set up and execute the precast lifts.