Project Summary

Client: CPBJH

Location: Whitehall St Footscray, VIC 3011

Crane: LTM1060 X 2

Project Overview

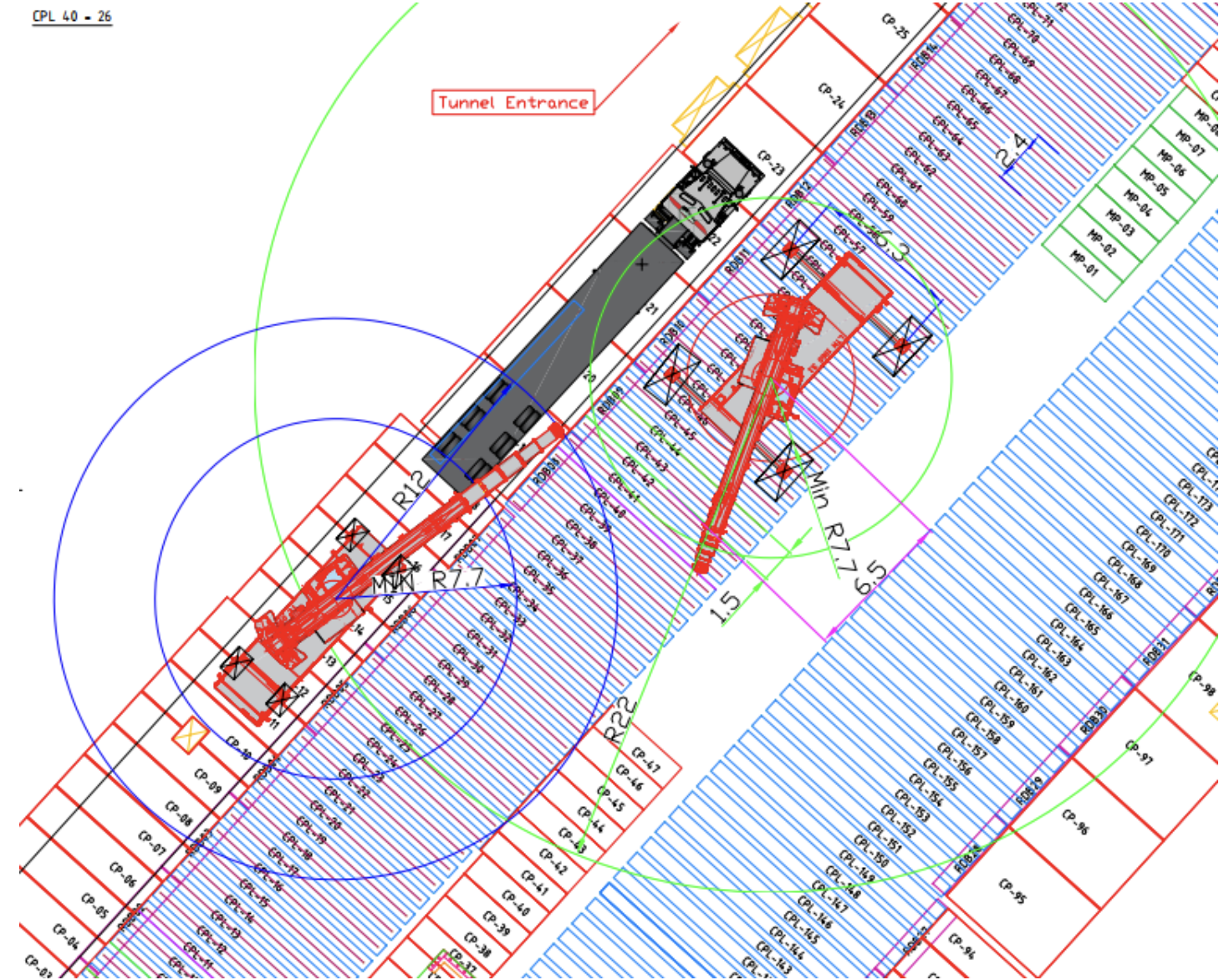

Premier Cranes was selected by CPBJH for the critical task of installing CPL Planks that will form the foundational concrete slab structure inside the West Gate Freeway tunnel.

This operation is a testament to Premier's expertise in adapting to the unique demands of complex infrastructure projects.

Challenges & Premier Solution

The project presented a unique set of challenges.

Notably, the restricted head space within the tunnel, hindered the rigging process.

Premier's planning team, renowned for their innovative approach, introduced a dual lift methodology to avoid the need for 60-degree rigging that would have otherwise been essential, yet challenging to maintain due to the constrained head space.

The new rigging solution involved connecting the shackles directly onto the clutches, seamlessly fitting the dual lift within the limited head space available.

Space constraints inside the tunnel such as the limited clearance of 6.7m from the ground to the top, also meant that configuring the cranes inside was not feasible.

To bypass this, counterweights were added on to each LTM1060 crane prior to their entrance into the tunnel.

The setup of the first crane utilised bog mats under fully extended outriggers, the crane was configured before reverse entering the tunnel with its counterweightand the boom slewed to the opposite side to allow for the precise pickup of the load from its designated slew radius.

However, the second crane's setup posed more of a challenge due to tighter space constraints. Premier's solution was to employ the VarioBase technology to short block the outriggers, coupled with EK timbers for optimal stability. Configured outside the tunnel with its counterweight, the crane straight navigated into the tunnel.

Both 60t Liebherr mobile cranes were set up on suspended slabs, a method validated for safety by the client's engineering team in collaboration with Premier's planning team, ensuring the load weights were within safe working limits.

Sequence of Operations

- Barricade work areas to secure the operation zones.

- Reverse the first LTM1060 into position, rig according to the lift plan, and prepare for the load delivery within the specified radius.

- After the truck reverses into the tunnel with the CPL Plank, set up the second LTM1060 in the designated position and rig as per the lift plan.

- Attach and secure rigging to both cranes and slew the booms over the loads.

- The rigger directs the crane operators to adjust the rigging, ensuring security and correct placement before the lift.

- Both cranes then hoist whilecarefully teling out the crame booms and slewing the load in synch to its final position, with the rigger overseeing the operation.

- Carefully lower the load into position, ensuring it is correctly secured before detaching the rigging.

Key to Project Success

The dual lift plank installation inside the West Gate Tunnel highlighted Premier Cranes' capability for clever and practical engineering solutions. The project's success was faurther underscored by the need for crane relocation after installing several slabs, demonstrating Premier's adaptability, precision execution and tightly managed project-logistics.