Project Summary

Project Overview

PROJECT OVERVIEW: As part of the West Gate Tunnel contract that Premier has undertaken since 2018, Premier was responsible for installing gantry support beams.

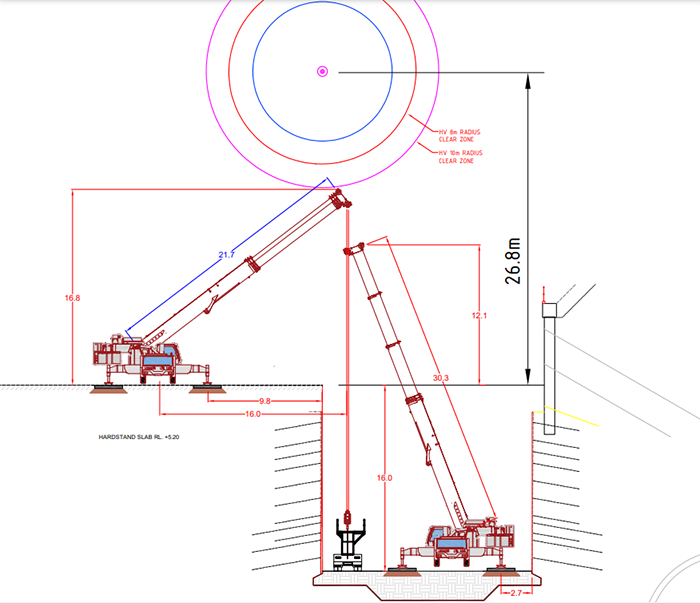

CHALLENGE: The project-specific challenges at the installation point, in the inbound southern portal included tight acces area & low hanging high voltage transmission lines that severely limited the boom extension capabilities. Moreover, there was challenging site access with an 800m long ramp on a steep grade just off the busy freeway. Additionally, when coming up with the best lifting solution, Premier had to take into consideration other trades and contractors that were working on the same areas, as well as come up with a lift plan based on tight crane set up areas.

SOLUTION: Given the layers of challenges, the planning process involved lengthy collaboration amongst Premier’s Heavy Lift Manager, Planning team of clever engineers and of course the client! Starting from finding the right way to unload the heavy beams from the trailer, we utilised Premiers LTM1250-5.1.

Premier’s lift plans included detailed information of the correct lifting and rigging equipment needed to successfully complete each installation. Given the only available crane set up area was under powerlines, our first solution was to use a single crane in the lower site area (16m). The challenge with lifting from a lower ground level was the amount of boom length required to lift the beams high enough for installation. After several lift plan revisions, the team decided to dual lift the beams using two cranes, while continuously supervising the transmission lines clearance to ensure the lifts were executed safely. The operators and the riggers used accurate and clear communication at all times, to ensure both crane movements were completely in synch. Whilst this solution may seem complicated, it was the best solution as the only other crane set up area was in the midst of live traffic and would have required a 600t crane!